Table of Contents

Ultimate Guide Stainless Steel Watches

In the world of horology, the material of the watch is as significant as the mechanism that powers it. Among the myriad materials used, stainless steel stands out for its durability, aesthetic appeal, and affordability. This guide will delve into the intricacies of stainless steel and its relationship with the art of watchmaking.

Understanding Stainless Steel

Stainless steel, an alloy of iron, carbon, and a minimum of 10.5% chromium, is renowned for its strength and resistance to corrosion and tarnish. The addition of other elements like nickel, molybdenum, or nitrogen enhances its properties, making it an excellent choice for various applications, including watchmaking.

There are several types of stainless steel, but the most commonly used in watches are 316L, 904L, and surgical grade. Each type offers unique characteristics that make them suitable for different watch styles and price points.

316L Stainless Steel

316L stainless steel is a standard in the watch industry due to its excellent resistance to corrosion, ease of maintenance, and affordability. It contains molybdenum, which enhances its resistance to certain types of corrosion, making it ideal for everyday wear.

Despite its lower cost, 316L stainless steel doesn't compromise on aesthetics. It can be polished to a high shine or brushed for a more subdued look, offering versatility in watch design.

904L Stainless Steel

904L stainless steel, also known as "Rolex steel," contains a higher percentage of nickel, chromium, and molybdenum, making it more resistant to corrosion and wear. It also achieves a higher luster when polished, making it a preferred choice for luxury watches.

However, 904L stainless steel is more challenging to machine and requires specialized equipment, contributing to its higher cost. Despite this, its superior quality and finish make it a worthwhile investment for high-end timepieces.

Surgical Grade Stainless Steel

Surgical grade stainless steel, also known as 316LVM, is a variant of 316L stainless steel with a lower carbon content and vacuum melting process. This process reduces impurities, making it hypoallergenic and suitable for wearers with sensitive skin.

While it's more expensive than 316L, its biocompatibility makes it a popular choice for watches intended for long-term wear.

The Role of Stainless Steel in Watchmaking

Stainless steel plays a pivotal role in watchmaking, contributing to the watch's durability, aesthetics, and wearer comfort. Its versatility allows it to be used in various parts of a watch, from the case and bracelet to the tiny components of the watch movement.

Moreover, stainless steel's resistance to corrosion and scratches ensures the watch can withstand the rigors of daily wear and maintain its appearance over time. This durability, combined with its affordability, makes stainless steel watches an excellent choice for both novice and seasoned watch enthusiasts.

Stainless Steel Watch Cases

The watch case houses the watch movement and dial, protecting them from dust, moisture, and shocks. Stainless steel's strength and malleability make it an ideal material for watch cases, as it can be shaped into various forms without compromising its durability.

Furthermore, stainless steel's resistance to corrosion ensures the watch case can withstand exposure to sweat and moisture, essential for dive watches and other water-resistant timepieces.

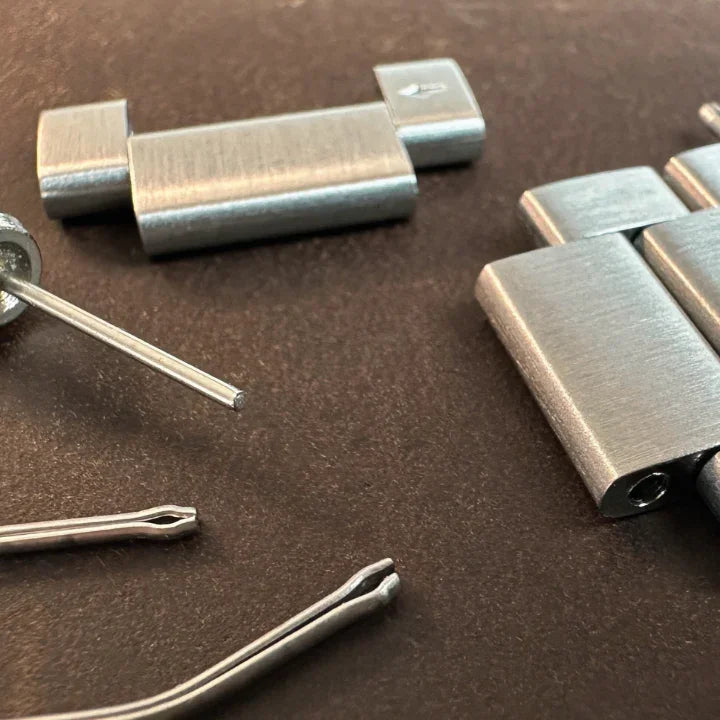

Stainless Steel Watch Bracelets

Stainless steel is also commonly used in watch bracelets due to its durability and comfort. Its hypoallergenic properties make it suitable for long-term wear, while its weight provides a reassuring heft without being overly heavy.

Additionally, stainless steel bracelets can be adjusted for a perfect fit, and their links can be polished or brushed for a variety of finishes, adding to the watch's aesthetic appeal.

Caring for Stainless Steel Watches

While stainless steel watches are designed for durability, proper care is necessary to maintain their appearance and ensure their longevity. This includes regular cleaning, avoiding harsh chemicals, and professional servicing.

Regular cleaning with a soft cloth and warm soapy water can remove dirt and oils that accumulate over time. It's also important to dry the watch thoroughly to prevent water spots or corrosion.

Avoiding exposure to harsh chemicals can prevent damage to the watch's finish. This includes household cleaners, chlorine, and saltwater. If exposure is unavoidable, it's recommended to rinse the watch with fresh water afterwards.

Lastly, professional servicing every few years can ensure the watch movement is in good working order and identify any potential issues early. This can include cleaning, lubrication, and replacement of worn parts, ensuring the watch continues to function accurately and reliably.

Conclusion

Stainless steel's unique combination of durability, aesthetic appeal, and affordability makes it a cornerstone of watchmaking. Whether you're a casual wearer or a discerning collector, understanding the role and care of stainless steel in watches can enhance your appreciation of these intricate timepieces and ensure their lasting beauty and performance.

Embrace the distinctiveness of stainless steel in the realm of horology with Söner Watches. As the only brand dedicated to crafting exclusively analog square watches, we invite you to join a select group of individuals who choose to make a statement. Discover our watch collections and find your perfect timepiece that not only complements your style but also sets you apart from the crowd. Discover our watch collections and step into a world where your wristwear is not just a timepiece, but a conversation starter and a symbol of pride.