Table of Contents

Vickers Hardness Steel Durability

When it comes to selecting high-quality materials for precision engineering and luxury items, such as watches, understanding their hardness is crucial. One of the most reliable and widely used methods for measuring material hardness is the Vickers hardness test. This blog post will delve into what Vickers hardness is, how it is calculated, and why it matters in the world of watchmaking and beyond.

What is Vickers Hardness?

The Vickers hardness test, developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd, measures the hardness of materials by determining their resistance to plastic deformation. Unlike other hardness tests, Vickers can be used for all metals and has one of the widest scales among hardness tests. The resulting hardness value, known as Vickers Hardness (HV), is a crucial indicator of a material's strength, durability, and wear resistance.

How is Vickers Hardness Calculated?

The Vickers hardness test involves a straightforward yet precise method:

-

Indentation Process: A diamond indenter, shaped like a pyramid with a square base and an angle of 136 degrees between opposite faces, is pressed into the material's surface under a specific load, typically ranging from 1 to 100 kgf.

-

Measurement: After the load is applied for a fixed duration, the indenter is removed, leaving an indentation on the material's surface. The diagonals of this indentation are measured using a microscope.

-

Calculation: The Vickers hardness value is calculated using the formula

-

Where:

- is the applied load (in kgf).

- is the average length of the diagonals of the indentation (in mm).

This formula effectively measures the load over the area of the indentation, providing a precise hardness value. Higher HV numbers indicate harder materials, meaning they are more resistant to deformation and scratching.

Why Vickers Hardness Matters

In the context of watchmaking, the hardness of the materials used in the construction of a watch case significantly impacts its durability and aesthetic longevity. Here's why Vickers hardness is crucial:

-

Scratch Resistance: Materials with higher Vickers hardness values are less prone to scratches and dents. This is particularly important for watch cases, which are subject to daily wear and tear.

-

Durability: A higher hardness rating means the material can better withstand impacts without deforming, ensuring the watch maintains its shape and appearance over time.

-

Precision: For intricate parts like those in a watch, materials with consistent and known hardness are essential for maintaining the precision and reliability of the timepiece.

-

Aesthetic Longevity: Harder materials keep their polished finish longer, preserving the watch's aesthetic appeal for years.

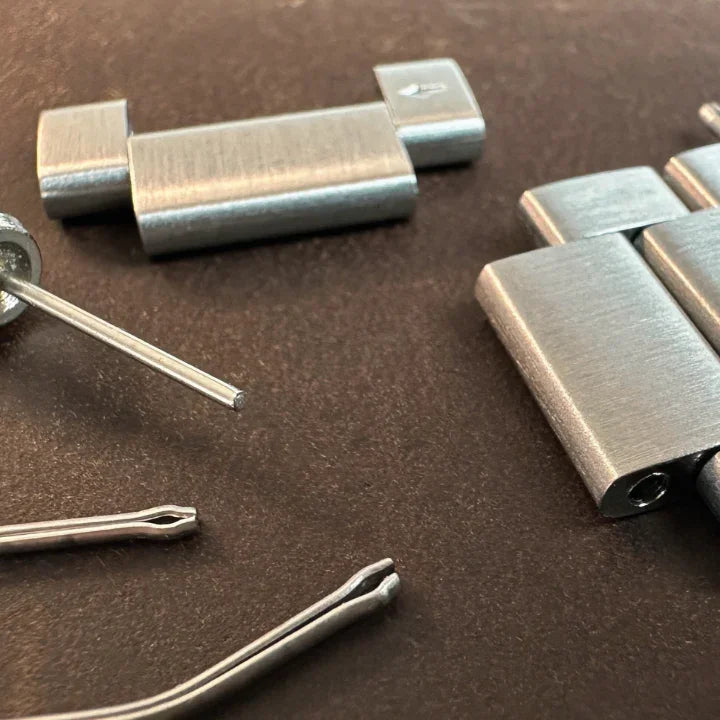

Vickers Hardness in Söner Watches

At Söner Watches, we understand the importance of using materials that stand the test of time. That’s why our watch cases are crafted from steel hardened to an impressive 800 Vickers (HV). This level of hardness ensures exceptional resistance to scratches and impacts, maintaining the pristine appearance of our watches even under rigorous daily use.

By choosing materials with a high Vickers hardness rating, we ensure that every Söner watch not only exudes luxury and style but also offers unparalleled durability. Whether you’re an active professional or a discerning collector, our watches are designed to withstand the demands of your lifestyle while looking impeccable.

Conclusion

The Vickers hardness test is a vital tool in the materials science and engineering fields, providing a reliable measure of a material's hardness and durability. For watch enthusiasts and manufacturers, understanding and utilizing high Vickers hardness materials is key to creating timepieces that are not only beautiful but also built to last. At Söner Watches, our commitment to quality is reflected in our use of 800 HV hardened steel, ensuring that our watches remain as striking and resilient as the day they were crafted.