Table of Contents

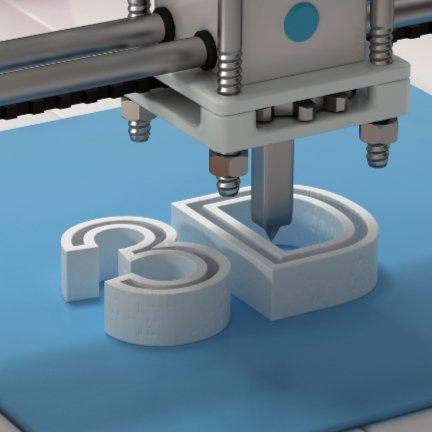

3D Printing in the Watch Industry

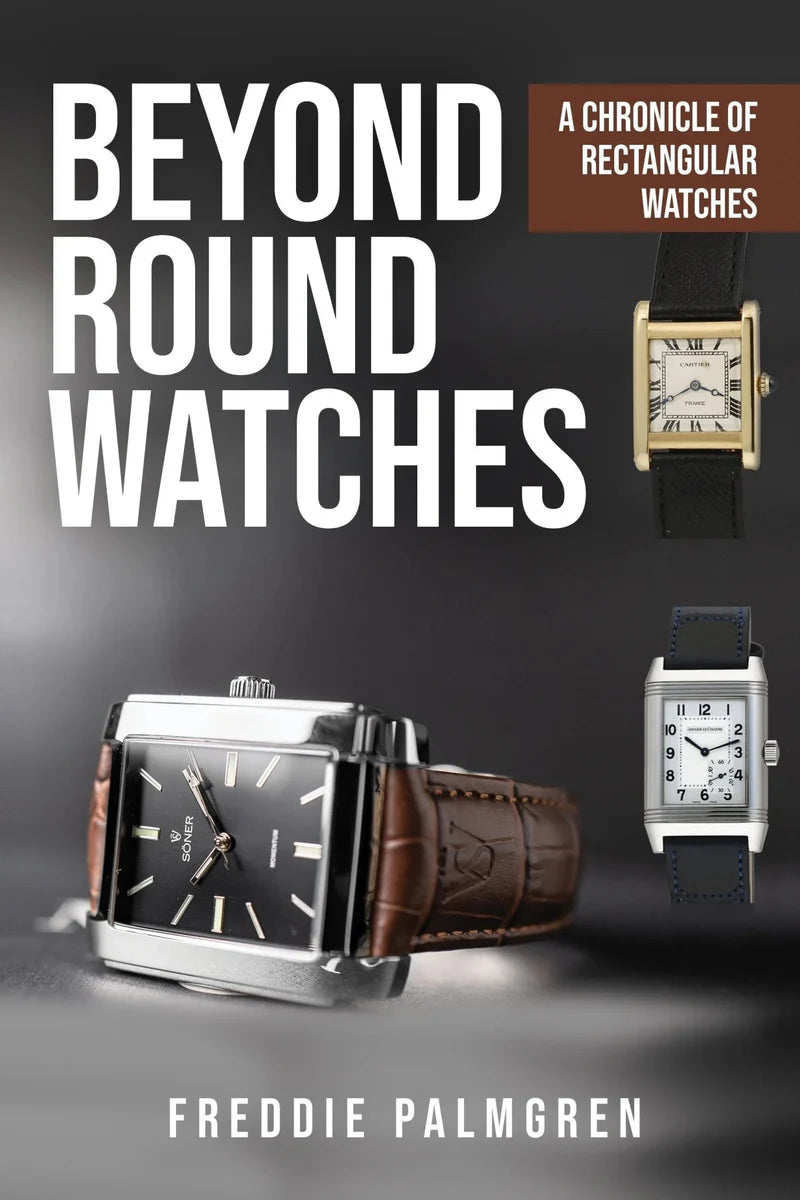

The watch industry has undergone a remarkable transformation in recent years, thanks to the advent of 3D printing technology. Gone are the days when designing and prototyping watches was a time-consuming and challenging process. With the aid of 3D printing, Söner Watches now have the ability to bring our creative visions to life rapidly and efficiently. This article explores how 3D printing has revolutionized the watch industry, allowing for faster design iterations, enhanced customization, and unprecedented levels of creativity.

1. Streamlining the Watch Design Process

Designing watches traditionally involved numerous iterations, with each prototype requiring significant time and resources. However, with 3D printing, Söner Watches can now create and test different designs in a fraction of the time. The process of finalizing case designs and measurements has become a breeze for us at Söner Watches. What once took weeks or even months can now be accomplished within minutes. This increased speed and efficiency have opened up new possibilities for experimentation and innovation.

2. Unleashing Creativity

The flexibility provided by 3D printing technology has unleashed a wave of creativity within the watch industry. We at Söner Watches are no longer constrained by the limitations of traditional manufacturing methods. With 3D printing, intricate and complex designs can be realized with ease. Whether it's intricate dial patterns, unique case shapes, or innovative strap designs, 3D printing allows for unprecedented levels of customization and personalization. We can now push the boundaries of conventional design, resulting in timepieces that are truly one-of-a-kind.

3. Prototype Testing and Refinement

In the past, creating functional prototypes involved significant time and financial investments. However, with 3D printing, Söner Watches can now produce accurate prototypes quickly and cost-effectively. This capability has revolutionized the testing and refinement process for us. We can now evaluate the functionality, ergonomics, and overall aesthetics of our watches through physical prototypes, identifying any flaws or necessary improvements before final production. This iterative approach ensures that the final product meets the highest standards of quality and precision.

4. Accessibility and Affordability

One of the most significant advantages of 3D printing in the watch industry is its increased accessibility and affordability. While traditional manufacturing techniques often required substantial investments in specialized machinery and tooling, 3D printing has significantly lowered these barriers. As a result, smaller and independent watchmakers like we at Söner Watches now have the opportunity to bring our unique designs to the market without the need for extensive resources. This democratization of the industry has led to a diverse range of innovative timepieces hitting the market, catering to various tastes and preferences.

Conclusion

The revolution of 3D printing has propelled the watch industry into a new era of design, innovation, and accessibility. This transformative technology has streamlined the design process, allowing for faster iterations and enhanced customization. It has unleashed a wave of creativity, enabling watchmakers like us at Söner Watches to push the boundaries of traditional design.

With 3D printing, prototype testing and refinement have become more efficient and cost-effective. The watch industry is experiencing a dynamic shift, where independent designers and established brands alike can bring their unique visions to life with greater ease and affordability. As 3D printing continues to evolve, we can expect even more groundbreaking advancements and a more diverse array of remarkable timepieces to grace our wrists.