Table of Contents

How Automatic Watch Works

The art of watchmaking is a centuries-old tradition that combines precision, craftsmanship, and innovation. One of the most fascinating aspects of this tradition is the automatic watch, a marvel of mechanical engineering that operates without a battery or manual winding. But how does an automatic watch work? In this comprehensive guide, we will delve into the intricate mechanics of automatic watches, exploring their history, components, and the science behind their operation.

The History of Automatic Watches

The automatic watch, also known as a self-winding watch, has a rich history that dates back to the 18th century. The first automatic watch was created by Abraham-Louis Perrelet, a Swiss watchmaker who sought to harness the energy generated by the wearer's movements.

Perrelet's invention was revolutionary, but it was not until the 20th century that automatic watches became widely available. The development of the rotor, a component that could rotate 360 degrees, was a significant milestone in the evolution of automatic watches. This innovation, introduced by Rolex in 1931, greatly improved the efficiency of automatic watches and paved the way for their widespread adoption.

Components of an Automatic Watch

Understanding how an automatic watch works requires a basic knowledge of its key components. These include the mainspring, the gear train, the escapement, the balance wheel, and the rotor.

The Mainspring

The mainspring is the power source of an automatic watch. It is a coiled spring that stores energy when it is wound. In an automatic watch, the mainspring is wound by the movement of the wearer's wrist, which causes the rotor to rotate.

When the mainspring unwinds, it releases energy that powers the watch. The rate at which the mainspring unwinds is regulated by the escapement and the balance wheel, ensuring that the watch keeps accurate time.

The Gear Train

The gear train is a series of gears that transmit the energy from the mainspring to the escapement. The gears in the train serve to reduce the speed of the energy release, which allows the watch to run for a longer period of time.

The last gear in the train, known as the escape wheel, interacts with the escapement to regulate the release of energy.

The Escapement and Balance Wheel

The escapement and balance wheel work together to control the rate at which the mainspring unwinds. The escapement is a mechanism that releases the energy from the mainspring in small, controlled increments.

The balance wheel, which oscillates back and forth, interacts with the escapement to maintain a steady rhythm. This rhythmic motion, typically 28,800 times per hour, is what makes the second hand on a watch tick.

The Rotor

The rotor is the component that sets an automatic watch apart from a manual watch. It is a semi-circular piece of metal that rotates freely with the movement of the wearer's wrist.

As the rotor spins, it winds the mainspring, providing the energy needed to power the watch. This means that as long as the watch is worn regularly, it will continue to wind itself and keep time accurately.

The Science Behind Automatic Watches

The operation of an automatic watch is a testament to the principles of physics and mechanical engineering. The watch harnesses the kinetic energy generated by the wearer's movements and converts it into potential energy, which is stored in the mainspring.

The release of this energy is carefully regulated to provide a steady power source for the watch. This process involves a delicate balance of forces and motions, all contained within the compact space of a wristwatch.

Conservation of Energy

The principle of conservation of energy is central to the operation of an automatic watch. This principle states that energy cannot be created or destroyed, only transferred or converted from one form to another.

In an automatic watch, the kinetic energy generated by the wearer's movements is converted into potential energy and stored in the mainspring. This energy is then gradually released to power the watch.

Friction and Wear

Friction is a key factor in the operation of an automatic watch. While it is necessary for the functioning of the gears and the escapement, excessive friction can cause wear and tear on the watch components.

To mitigate this, automatic watches are designed with jewel bearings, typically made of synthetic ruby or sapphire. These jewels reduce friction and wear, prolonging the life of the watch.

Gravity and Motion

Gravity and motion also play a crucial role in the operation of an automatic watch. The rotor, which winds the mainspring, relies on gravity and the motion of the wearer's wrist to rotate.

The balance wheel, which regulates the release of energy from the mainspring, is also influenced by gravity. To ensure accurate timekeeping, watchmakers must carefully adjust the balance wheel to compensate for the effects of gravity.

Conclusion

The automatic watch is a marvel of mechanical engineering that combines precision, craftsmanship, and scientific principles. Its operation is a testament to the ingenuity and skill of watchmakers, who have honed their craft over centuries.

While the automatic watch may seem like a simple accessory, it is in fact a complex machine that embodies the history, art, and science of watchmaking. So, the next time you glance at your wrist to check the time, take a moment to appreciate the intricate mechanics at work in your automatic watch.

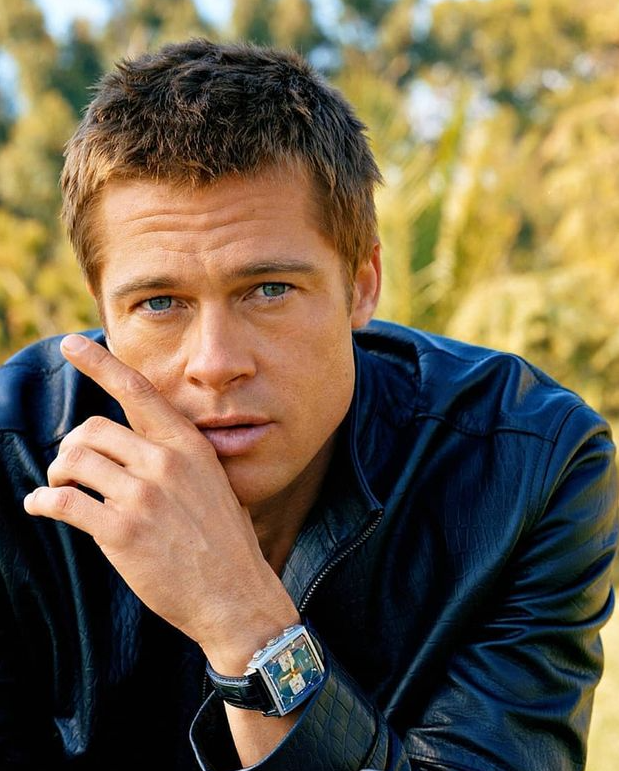

As you marvel at the sophistication of your automatic watch, why not elevate your style with a timepiece that's as unique as you are? Söner Watches invites you to Discover our watch collections, where each square watch is a statement piece, crafted for those who dare to be different. Embrace the exclusivity of being part of a select group that knows the value of standing out. Your journey with Söner is more than just about telling time; it's about wearing a piece of art that reflects your individuality and accompanies you through every moment of your life. Join us in defying the norm and experience the extraordinary with Söner Watches.